PP Compounder Elbows Out Production Snafus

June 6, 2017

The Plastics Group of America eliminates monthly production stoppages, improves quality, and slashes maintenance expenses by installing new elbows on a pneumatic conveying line.

Article Post: 6/28/2017

JIM CALLARI – Editorial Director/Associate Publisher, Plastics Technology

At The Plastics Group of America, pneumatic conveying of its Polifil line of filled and reinforced polypropylene compounds caused 90° sweep elbows to fail monthly, a problem the Woonsocket, R.I., compounder solved by installing Smart Elbow deflection elbows from HammerTek, Bethlehem, Pa.

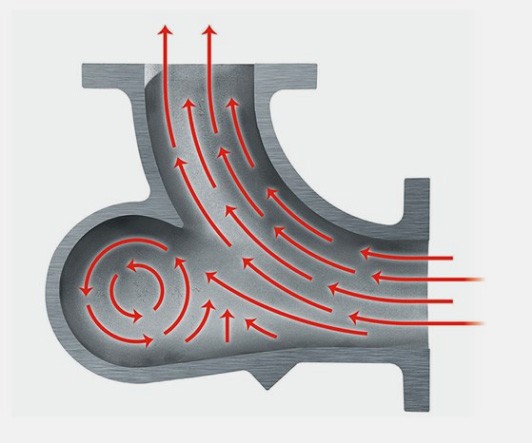

The vortex chamber of the HammerTek deflection elbow protrudes partially beyond the 90° flow path, causing a sphere of material-in-air to rotate in the same direction as the air stream that powers it, gently deflecting incoming material around the bend without impacting the elbow wall.

The Plastics Group replaced conventional sweep elbows with HammerTek deflection elbows in 2013, none of which has needed replacing. By preventing material impact with the elbow wall, the company has prevented elbow wear, the generation of fines, and the frictional heat that previously caused the formation of angel hair and streamers.

According to Ed Joanis, maintenance director, The Plastic Group’s proprietary compounds, containing up to 40% glass fiber and minerals such as calcium carbonate and talc, were wearing away the elbows, whose 90° angles created impact points for the pellets traveling through the lines. And that’s not all: “The impact of the abrasive resins hitting the inside walls of the elbows at high speed not only created fines, but heated the elbows, causing pellet surfaces to melt and form angel hair and streamers, creating quality issues downstream in our compounds,” Joanis explains.

Replacing each of the six elbows cost the compounder an hour of downtime plus the cost of labor. The price of buying 72 or more replacement elbows a year ran well into the tens of thousands of dollars. The Plastics Group went searching for a solution, and ended up replacing the six 90° sweep elbows with the HammerTek deflection elbows—two per line.

The Smart Elbow design incorporates a spherical vortex chamber that extends partially beyond the 90° flow path, causing a ball of pellets to rotate in the same direction as the air stream, gently deflecting incoming pellets around the bend.

In addition to preventing pellets from impacting the elbow wall, the vortex chamber causes the material to exit the elbow evenly and return rapidly to a laminar, steady-state flow within the conveying line. The airstream sweeps the vortex chamber clean after the material feed is shut off.

“None of the deflection elbows has needed replacing after being installed in May 2013, eliminating the cost of replacements, labor, and downtime,” says Joanis. “The gentle deflection action also reduces the formation of fines, dust, and angel hair, improving the quality of our compounds and finished products.” He adds, “Maintaining structurally sound elbows also minimizes potential injury due to blowouts and material spills.”

The Smart Elbow replacements are cast of ductile iron and measure 18 × 18 in. × 3 in. diam. The elbows cost more than the sweep versions they replace, Joanis acknowledges, but they yield a rapid ROI due to long life and reliable performance.

In Woonsocket, The Plastics Group conveys about 3300 lb/hr of reinforced resins through two of the lines during compounding operations, and 1200 to 1500 lb/hr through the third line. These resins and others (including reprocessed materials) used in the company’s Polifil compounds end up in a range of consumer and industrial products.

The compounder began operations in 1973 in a small plant. It now processes materials in a 250,000 ft2 facility, and plans to add another material conveying line that will also be equipped with Smart Elbow deflection elbows.